Best viewed using:

Internet Explorer

or

Mozilla Firefox

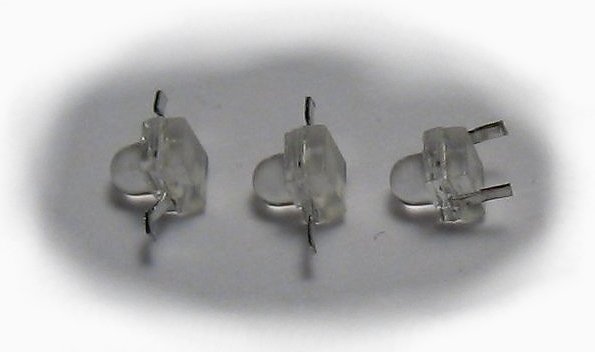

Shown above are three of our Subminiature LEDs with their leads formed in different ways.

On the left is the way the leads are shaped when the LED is unpackaged. In this position the face of the flat leads are in line with the face of the square LED housing. This would accommodate mounting the LED against a circuit board with the domed portion protruding through a hole in the board. This will work fine for panel-mount type applications.

In the center view, the leads have been straightened out flat by squeezing them with a pair of small needle-nose pliers.

In the right-hand view, the leads have been bent straight down along the sides of the LED's square base. This provides the smallest footprint and still allows easy soldering of wires to the leads. We used this form and attached several groups of the LEDs to strips of styrene using standard styrene cement. for a demonstration module for our N8103 Booster Board (see below)

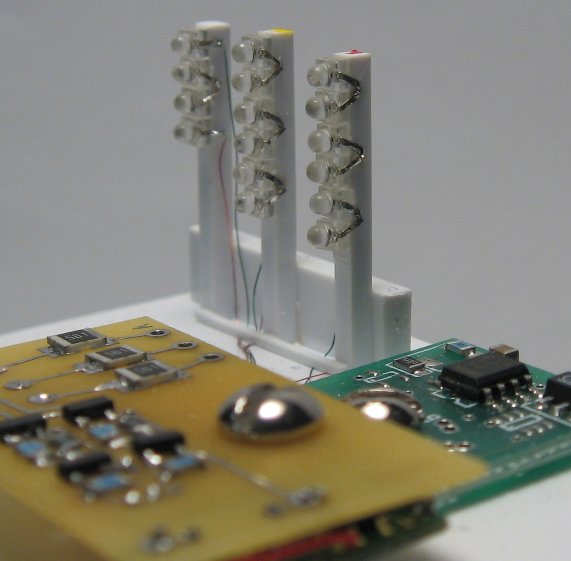

Here we twisted the leads at a slight angle so they could overlap each other for easy soldering in a series wired group. The group in the foreground are 6 N1042 reds, the middle are 6 N1043 yellows, and the background (left-hand) group are 4 N1044 greens.

The Booster is a N8103-3 three-channel board. The red group is being driven by a N8033 Gyralight Simulator, the yellow group by a N8031 Marslight Simulator, and the green group by a N8011 Emergency Flasher. Each group doing a different rate and sequence. When the Booster is turned on, it is a dazzling sight to behold.

Another possible example of lead forming might be for attaching a N1042 red LED to the underside of a caboose roof overhang as an end-of-train flasher. After attaching wires, the LED leads could even be further bent up against the back of the LED housing to totally minimize the overall size. After gluing into position, the LED housing could be painted the same color as the caboose, leaving only the domed lens exposed.

© 2008 Ngineering